A step by step guide for Groundnut oil making process, business plan:

Today, let us discuss the groundnut oil production process, extraction methods, and business plant including groundnut oil plant (machine) cost in India.

Groundnut oil is also known as peanut oil or Arachis oil, is a mild-tasting vegetable oil expressed from groundnut kernels. Groundnut oil is generally used in cooking, including frying, basting, and the manufacture of margarine and shortenings. Groundnut oil is light yellow transparent edible oil with clear color and lecture, pleasant fragrance and good taste is relatively easy to digest.

Groundnuts or peanuts are a popular source of food throughout the world. And the groundnut oil, however, can be used for cooking, they can be used as a shortening or as a base for confectioneries and they can be used to make peanut butter. Groundnut kernel contains 45 to 55% of oil. The Groundnut oil obtained from the kernel is yellow to greenish-yellow in color. The meal is a very important component of feeds for poultry and cattle. Groundnut oil is an organic material oil that derived from peanuts, noted to have the aroma and taste of its parent legume. Peanuts or Groundnut oils can be extracted in various ways. Always method used depends on the oil.

Groundnut oils are extracted by using a solvent like hexane, while aromatic oils are extracted with different methods including steam distillation and the cold pressing method. In all of these options, the goal of extraction is to produce pure oil free from contaminants and traces of the original plant material.

India is the second-largest producer of peanuts after China. Groundnut or Peanut is the largest oilseed in India in terms of production. It accounted for about 35.99 percent of the oilseeds production of the country during 2007-08. Generally, 2.5 kg of groundnut to produce 1 liter of the groundnut oil. The cost of procurement and processing of the groundnut or peanut is around Rs. 90/kg. Hence, simple math says that Rs. 225/liter is the raw material cost.

Major Groundnut oil-producing states in India

In India groundnut or peanut is grown over an area of 6.9 million hectares with a total production of 5.3 million tonnes. Groundnut cultivation is mainly confined to south Indian states, viz, Gujarat, Andhra Pradesh, Karnataka, Tamil Nadu, and Maharashtra. The other important states grown Groundnut are Madhya Pradesh, Rajasthan, Uttar Pradesh, and Punjab.

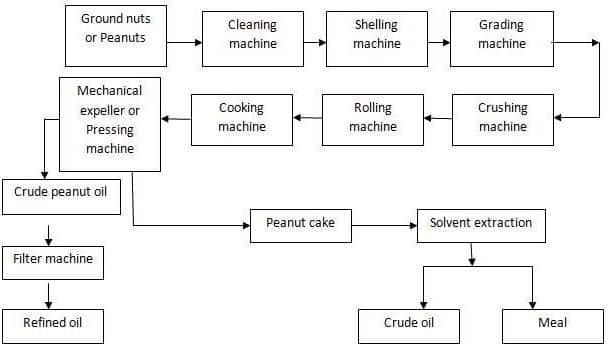

The general process of Groundnut oil production

From harvested groundnuts to pure edible peanut oil or groundnut oil production is a complex process. The main procedure is groundnuts preprocessing, prepressing, solvent extraction, crude peanut oil refining.

You may also like Growing Onions from Seed, Planting, Care, Harvesting.

The Groundnuts must be pre-processed before sending to the expelling department, the kernels need to be cleaned, shelled, cracked and cooked by special seed processing machinery. Then the preprepared peanut kernels will be transported to the prepressing workshop in where these raw materials could be first expelled by screw oil press machines. However, the screwing process of pressing is a high residual oil rate. In this time, the chemical method solvent extraction will be a good method to fully extract peanut oils. The solvent extraction method can create the residual oil rate of the groundnut meal below 1%. Therefore, for edible use, the pressed crude groundnut oil needs to be refined by filter presses or oil refining plant.

Groundnuts solvent extraction process

Generally, the Groundnut or peanut solvent extraction is a procedure which involves extracting oil from oil-bearing materials by treating it with a low boiler solvent as opposed to extracting the oils by mechanical pressing methods that are expellers, hydraulic presses, etc. The solvent extraction process recovers almost all the oils and leaves behind 0.5% to 0.7% residual oil in the raw material, such as peanuts solvent extraction plant or ground nuts solvent extraction plant, etc. In the case of mechanical pressing, the residual oil left in the oil cake can be anywhere from 6% to 14%.

Groundnuts are first decorticated to remove the husk. The Groundnut kernels so obtained have oil content over 48%. The kernels are subjected to mechanical extraction process with the help of screw presses. The resultant cake has residual oil content changeable from 8 to 12% depending on the extent of pressing. The pre-pressed cake is subjected to solvent extraction for recovery of the residual oil.

The raw material for Groundnut oil production:

The principal raw material essential for the production of groundnut oil is groundnut seed. And you could procure this locally. The seed gives 44.5 to 50% oil, 50-55% meal. However, other required raw materials for Groundnut oil production are caustic soda, bleaching earth, and packaging consumables.

Equipment used for Groundnut oil extraction process:

List of the equipment used for Groundnut oil extraction process will be given below;

- Self-regulation vibrating sieve

- Magnetic separator

- Cleaning sieve

- Groundnut shelling machine

- Groundnut Kernel Grading Machine

- Peanuts Crushing Machine

- Five-layer Vertical Steam Cooker

- Electrical Cooker

- Peanut Rolling Machine

- Mechanical expeller

- Filter machine

Groundnut oil extraction process:

Groundnut oil processing process, based on mechanical pressing technology, is normally grouped into three stages they are groundnut seeds preparation, groundnut pressing, and rude groundnut oil refining.

The complete Groundnut oil extraction process can ensure the nutrition, flavor, safety, and fragrance of peanut oil. The different stages of Groundnut oil extraction process mainly composed of cleaning, shelling, grading, crushing, rolling, steaming or cooking, pressing, filtering and refining.

Cleaning:

The first step in preparing oil seeds for Groundnut oil extraction is to clean them. Clean accurately so that the oil is not contaminated with foreign materials. Therefore, this helps to proceed with the extraction process as efficiently as possible. During the procedure, carefully inspect the seeds to remove stones, sand, dirt and spoilt seeds. Additionally, you can use dry screening method to remove all material that is over or undersized. Sometimes washing is resorted to but it must be avoided as the plant tissue will have to be dried at a later stage.

You may also check Organic Vegetable Farming in India.

The raw materials for Groundnut oil extraction should be fresh, full-grained, undamaged, mildew-free, and free of insects and have not undergone an aging period. The cleaning procedure can remove the immature, damaged and moldy grains. The equipment used for this process will be self-regulation vibrating sieve, magnetic separator, cleaning sieve, etc.

Shelling:

Groundnuts with shells should use Groundnut sheller to remove the shells to increase the oil yield, improve the quality of the oil and cake and smooth the following peanut oil production process. The equipment used for this process will be the Groundnut shelling machine.

Grading:

Some of the Groundnut oil production plants may add this process to separate the small peanuts and large peanuts for different treatments. The equipment used for this process will be the Groundnut Kernel Grading Machine.

Crushing:

This procedure is to remove the red skin by crushing the Groundnut kernels. Then obtain rid of the red skin by wind separator. At the same time, large size Groundnut kernels are crushed into a smaller size. The moisture of crushed Groundnuts can be better controlled. The equipment used for this process will be the Peanuts Crushing Machine.

Rolling or grinding:

After crushing, Groundnuts are rolled through the instantaneous extrusion force between the two rollers to form the embryo slice, the shape of the peanut is changed, the oil path is shortened, and this is beneficial to the peanut oil extraction. The seed is not generally pressed whole since oil extraction is more efficient if the seed is in smaller particles. Herein lies the relevance of the grinding procedure. Grinding is the process for reducing the particle size. Also, you can use small motor powered hammer mills for the unit operation.

Another alternate process used for the reduction of particle size is rolling the oilseeds to generate flakes for oil extraction. Many large-scale commercial plants find this mainly effective approach. Additionally, with large oilseeds, it can be necessary to grind the seed first, and then put the pieces through the flaking rollers. The equipment used for this process will be Peanut Rolling Machine.

Steaming or Cooking:

This procedure is to adjust the moisture of peanut embryo slice by changing the temperature to develop the oil extraction rate and ensure the final peanut oil has a strong aroma. The equipment used for this process will be Five-layer Vertical Steam Cooker, Electrical Cooker.

It is not too late to check Basmati Rice Farming.

Pressing:

The steamed or cooked peanut embryo slices are then pressed by Groundnut oil press machine for oil extraction. The screw peanut oil or Groundnut oil machine can ensure the original cell structure of the peanut is destroyed under mechanical force to obtain a pressed crude oil.

During processing, press the conditioned oil seeds or oil-bearing material using a lever press, hydraulic press or a mechanical expeller to remove the oil.

Peanut oil pressing methods

Divided by pressing temperature, there are two types of peanut oil pressing methods they are hot pressing technology and cold pressing technology.

Hot pressing method is the traditional process of peanut oil. Peanut oil is steamed fried and pressed, generally at a temperature above 120 ℃ with a high rate of oil output. But because of the high production temperature, the peanut protein is generally severely denatured and the lose a great number of nutrients.

Cold pressing method refers to the oil production technology which is conducted temperature under 60℃. Before pressing method, normally uses the process of removing the red skin, which is beneficial to the reserve of nutrients and the comprehensive utilization of peanut protein in peanut oil.

Filtering:

Generally, crude peanut oil can include some organic impurities that can be easily removed by edible oil filter machine or other type’s oil filter machine.

Refining:

The crude peanut oil or Groundnut oil that is filtered by the oil filter machine is pure and clean. But it still contains several oil-soluble and in oil-soluble impurities. Therefore, it is essential to equip the peanut oil production plant with professional edible oil refinery equipment to get them off and obtain the refined high-quality peanut oil.

Cost of Groundnut oil extraction machine:

Generally, the cost of Groundnut oil extraction machine will be approximately Rs 1.8 Lakh/Piece.

You may be interested in Growing Arugula Plants.

Hello

I am Ankit Patel a Young entrepreneur looking for peanut oil business, and I need help from your side about business from the first step how to start the business , what is process n all.

Thank you

very good activity

Hi I a farmer from Maharashtra.I need to start a small groundnut oil factory in my farm.can any one pls suggest me from whr I can start..I saw lot of small machines which can give 4/6kg oil in an hr..as i am farmer i can grow groundnut in farm..

I need help from your side about business from the first step how to start the business , what is process n all.

Thanks you.

hi, i am in groudnut oil extraction business (cold pressed, chemical free) on a small scale. I need guidance from you to procure moister free, good oil content seeds. i want to expand my business. i am from Mumbai and do not get good variety of seeds from mandi i.e. wholwsellers in Mumbai and also rate if very high.

thanks

Hi, I am chetan patel from west Africa but I am indian from Junagadh Gujarat. If you want to start oil mill at Africa then I am with you because I want to start oil mill here. Actually I have lots of experience of Oil mill and cotton ginning. Here very good groundnut with per kg 30rs. and price will be not changed whole year because here is not satta bazar.

My whatsapp is continue at Africa so you can contact me.

With regards

What is the name of the variety of peanut.

I am a farmer and supplier of big lot ground nut. I can provide big lot of high quality ground nuts which contains good amount of oil content. Kindly clarify which grade of ground nut you use for oil making and Minimum quantity require.

I want know about groundnut.

Hi i have a oil manufacturing unit.. and i am in search of peanut farmer for direct supply of peanut in which both side will be benifitted…..

I was given an assignment, I really need it. The question goes as thus, what are the methods of grading in oil, it’s advantages and disadvantages?

Hi, My name is Mr. Subhash Wadkar,

I am professional for processing of edible oils working in Africa for many years. Now I want to start my own crushing unit for groundnut, but I really have doubts about the loss and forain material % for calculating its recovery after the process. Can any one guide me on retrieval that what is the standard range of F M content for groundnut process.

pls give me idea where we get ground nuts oil making machine

Hello, I am Mr Collins from Benin city ,Edo state ,Nigeria. I have just pick interest in production of grand nut oil in Benin . I have already made the provision for the supply of a machine for this business. So please I want to be properly guided on the business. And again I want the step by step process of this production and the marketing. Thanks. Collins

Thanks for this forum, it’s of a great opportunity and pleasure to read different thoughts and questions from across the globe.

I am from Northern Uganda and our region is the leading in groundnuts production.

I hope to submit my questions as I encounter challenges in this industry.

Am Blessing from Nigeria am looking in starting up a batch production of refined groundnut oil in my country but I need guidance on how to go about it and the variety of groundnut to use, and also how to remove odor in cold pressed groundnut oil

Your post is a valuable resource for anyone looking to expand their knowledge on the topic. It’s thorough and well-explained.