Rice bran oil extraction process

Today, we learn the subject of rice bran oil extraction, the refining process. We also explain the rice bran oil process flow chart.

Introduction of Rice bran oil:

Rice bran oil is a form of oil produced from the hard outer layer of rice, which is known for its high smoke point and mild flavor. Rice bran oil is produced from rice bran, an oily layer in between the paddy husk and white rice. This oil is the oil extracted from the hard outer brown layer of rice called chaff or rice husk. It is known for its high smoke point of 232°C (450°F) and mild flavor, making it appropriate for high-temperature cooking methods such as stir frying and deep frying.

The Rice bran oil is known as wonder oil for its numerous health advantages. It has a number of benefits over other edible oils because of the presence of a unique antioxidant known as oryzanol. Rice bran oil is regarded as a miracle product obtained from the outer layer of the brown rice. Rice bran is by-product obtained during rice milling function. This is golden reddish cuticle obtained after removal of the husk and through polishing of the rice.

Characteristics of Rice bran oil:

Rice bran oil will give an improved realization of paddy to Indian farmers.

It is considered better cooking oil because of Rice bran oil characteristics;

- Most ideal fat composition.

- RBO is an excellent alternative for those who have an intolerance to other cooking oils because of its hypoallergenic effect.

- Rice bran oil has a very high smoke or burn point, making it perfect for deep frying, pan or stirs frying.

- Rice bran oil creates fewer polymers or less greasy than other oils meaning better flavor and easier clean-up.

- Food cooked with this oil absorbs up to 15% to 20% less oil. This unique property of less oil absorbing and light viscosity effects in reduced calories, better-tasting food, economical and enhanced flavor, and palatability.

- RBO has excellent oxidation stability.

Rice bran oil:

Here, we explain what part of rice is rice bran and its uses;

Rice bran is the very thin layer of brown rice. It is the main nutritious part of rice. Rice bran is very high in vitamins and nutrients. Rice bran oil, not fiber, lowers cholesterol in healthy, hypercholesterolemia individuals. Because there were no substantial differences in the fatty acid composition of the diets, the reduction of cholesterol seen was due to another component there in the rice bran oil. Rice bran oil is mainly used in cosmetics because it’s a great moisturizer. Rice bran oil contains natural Vitamin E, flows nicely. It presents moderate penetration and leaves no greasiness or stickiness on the skin. It is an excellent carrier oil.

You may also check the How to Grow Taiwan Guava for Profit.

The manufacturing process of Rice bran oil:

Generally, Rice bran oil can be extracted by chemical solvents or pressed directly from rice bran. Here we recommend small capacity Rice bran oil can choose expelling pressing method, while large capacity takes the solvent making technique. We have to mention that hot extraction method which would obtain more oil yield and purer edible oil than the cold pressing method. When refers to Rice bran oil production, the following three processing steps are important they are raw material preparation, Rice bran oil extraction, and crude oil refining.

Rice bran raw material preparation:

Like other oil bearing materials, before making oil from rice husk, these raw materials must have been fully prepared. Rice bran is first screened and then heated by the steam process at a temperature higher than 100°C to stop Lipase hydrolysis in rice bran prior to the extraction process.

Extraction:

You can extract the crude rice bran oil either by a mechanical process with oil presses or by a chemical method with solvent. After proper preparation, the bran is fully stabilized and sent to an extraction region where oil is removed, yielding two products, a high-quality crude rice bran oil, and defatted rice bran.

Then the rice bran oil is pumped into the refining machinery to generate different grades of Rice bran oil. The refining process generally includes filtering, neutralization, degumming, decolorization, deodorization, and dewax, etc.

Rice bran oil refining:

Crude rice bran oil is further processed by the refining process, which removes the majority of free fatty acids and provides oil with minimal processing suitable for a variety of animal or agricultural applications. Edible oil bleaching normally leaves minor flavor and odor compounds that must be eliminated by steam distillation before packaging. However, those customers that require de-waxed oil have their oil go through a de-waxing process before distillation.

Steam distillation is the final step in the edible oil procedure and it is here that any off flavors and residual free fatty acids left in the oil are removed. Once the Rice bran oil has been fully processed, it is ready for packaging into retail bottles, food service pails or bulk drums.

Oil extraction process:

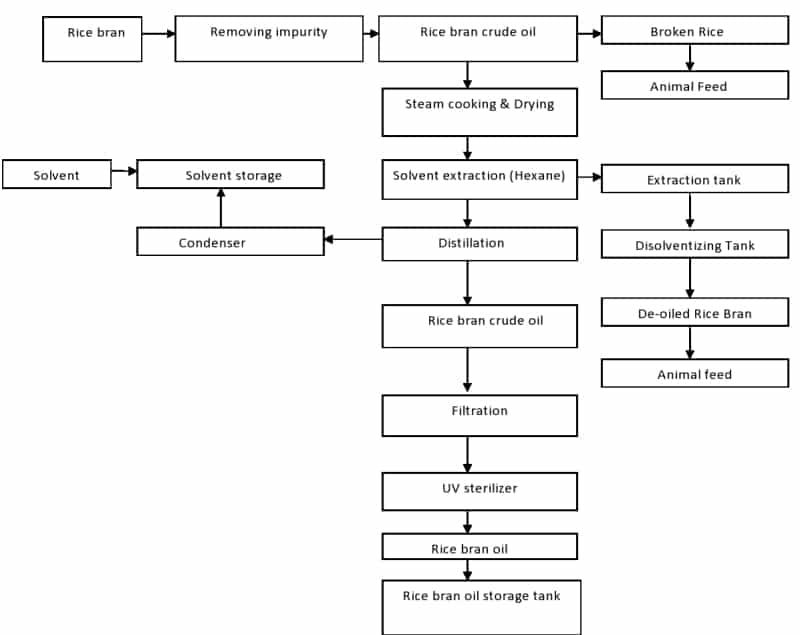

Let us find out the process of Rice bran oil extraction;

Rice bran oil is obtained by extraction of rice bran which is a by-product of the rice milling industries. There are several techniques used for the extraction process of the Rice bran oil, but solvent extraction using hexane is the most popular used conventional process for commercial extraction.

Rice bran oil expelling relies on very high-quality Rice bran oil expellers. After the well-set rice bran is put into the feeder of the expeller, a screwworm will transport the rice bran advance. As the screwworm moves, space becomes smaller, thus squeezing Rice bran oil out. Then the fresh RBO seeps out through the small openings in the bottom of the squeezing barrel where the Rice bran oil cake cannot pass through and separating Rice bran oil from oil cake.

After collecting Rice bran oil cake, Rice bran oil extraction comes with the help of food grade solvent, generally hexane. Principle of Rice bran oil extraction works on the countercurrent and moving the bed with variable bed height and different speed mechanism to make sure the permit of excellent penetration and percolation of solvent for absolute extraction. Then the distillation process begins in the vacuum, and the extracted rice bran oil is collected by vaporizing solvent out for later recovery.

You may be interested in Poplar Tree Plantation in India.

Mechanical pressing (Cold pressing)

Mechanical pressing is traditionally the most popular oil extraction process for oilseeds globally. It has been in use particularly by small and medium scale oil extraction industries for commercial Rice bran oil extraction in some countries like Thailand. The procedure is less expensive and less labor-intensive than using solvent extraction methods. The safety and simplicity of the procedure is an advantage over the efficient solvent extraction techniques. This process does not involve heat or chemical treatment, thus making it an interesting alternative for conventional practices because of consumer concern for a natural and safe product.

The mechanical pressing process is of two types, screw, and hydraulic press. The screw press is also called an expeller, it is very simple, easy to maintain and operate by semi-skilled workers. In comparison, the screw press or expeller is continuous and produces a slightly higher yield than the hydraulic press. The process involves continuous pressing using expellers (Screw press).

Expellers consist of a screw rotating inside a cylindrical cage or barrel and the material is fed between the screw and the barrel and then propelled by the rotating screw in a direction parallel to the axis. The gradual increase in pressure help to discharge the oil which comes out of the press through the slots provided on the periphery of the barrel and the residual pressed cake move in the direction of the shaft for discharge. However, for the extraction process of RBO using this method, only about 9 to 10% of the bran weight was found to be extracted by pressing. Extraction of oleiferous seeds by these methods revealed about 80 to 85%, while it was found that 75% of oil can be recovered from algae. Although mechanical pressing results in high-quality oil, the yield is relatively low and its normally used for small scale extraction, specialty products or as a pre-press operation in a large scale solvent extraction plant. To make this process more effective, further modification in the design is required which will help to increase the oil recovery.

Solvent extraction process

The solvent extraction process can be used to recover oil from any materials with low oil content, or for pre-pressed oil cakes in order to obtained high oil content. Hexane is the most normally used solvent for this method, it is relatively cheap and excellent for oil extraction. Some short chain alcohols such as ethanol and isopropanol have been proposed as an alternative solvent for the extraction process because of their greater safety. The yield of about 92% of the oil was obtained from the hexane extraction process of ohmic heating-stabilized rice bran. About 42.7 to 99.9% yield of oil from rice bran using ethanol to rice bran ratio of 2.5:1 and 4.5:1, and temperature of 60-90°C. Increasing the extraction temperature from 40°C to 60°C and solvent (hexane and isopropanol) to bran ratios (w/w) of 2:1 and 3:1 increased the RBO yield. Extraction at 60°C for ten minutes with 3:1 solvent to bran ratio using hexane solvent yielded about 3.6% more oil, while extraction with isopropanol produces 6.4% more oil than at 40°C. The yield of liquid propane was created to yield about 22.4% of oil in kg of rice bran at 0.76 MPa and ambient temperature.

An RBO was extracted with isopropanol and hexane at 40°C for 15 min. The hexane extracted almost 40% more oil than the isopropanol solvent, though increasing the temperature up to 120°C. The yield of hexane solvent did not increase but the isopropanol extracted 25% more Rice bran oil than hexane under similar conditions. About 99 to 99.5% of the oil was reported to be extracted by solvent extraction from oleiferous seed. The crude Rice bran oil obtained from this extraction procedure is mostly further subjected to chemical or physical refining to meet the specifications of food-grade vegetable oil. The organic solvent (usual hexane) mainly used is, however, flammable, volatile, toxic and pollutes the environment. Even though the use of hexane for extraction is considered efficient and widely used, it has some undesirable as mentioned earlier.

You may also check the Kadaknath Egg Production.

Storage Rice bran oil

Rice bran oils should be tightly capped and kept in a cool dark place like a pantry. Dark colored bottles can protect oils from the sun.

If you do refrigerate your Rice bran oil and it may become semi-solid in the cold. Just let it sit for 15 to 20 minutes at room temperature and it will return to liquid form.

If stored correctly, Rice bran oil should last about 1 to 2 years from the date it was bottled. The “Best by Date” generally reflects this time frame.

Cost of automatic Rice bran conditioner and oil:

The cost of automatic U type Rice bran conditioner will be approximately Rs 85,000/Piece and the cost of Rice bran oil is Rs 80/ Litre.

Some facts about Rice bran oil:

- Rice bran oil good because it has a balanced amount of monounsaturated, polyunsaturated and saturated fats. It is considered heart-friendly oil that can help improve your cholesterol. Rice bran helps lower cholesterol because it contains the right amount of oryzanol which is an antioxidant.

- It is possibly safe for most people when added to baths, but it can cause itching and skin redness.

- Generally, Rice bran oil contains a higher percentage of vitamin E than olive oil.

- Rice bran oil is popular as one of the healthiest cooking oils because it has the most balanced amount of PUFA (polyunsaturated fats) and MUFA (monounsaturated fats) and is rich in Vitamin E.

- Actually, Rice bran oil contains beneficial compounds that contribute to its resistance to oxidation, as well as the health of consumers. However, concerns have surfaced in recent years related to the heavy metal substance of rice and rice‐derived products. Rice is recognized to take up arsenic at a higher rate than other grain crops.

- If you do refrigerate Rice bran oil it may become semi-solid in the cold. Just let it sit for 15 to 20 minutes at room temperature and it will return to liquid form.

- Fortune Rice bran oil is India’s highest selling rice bran oil. Refined Rice bran oil with the goodness of Gamma Oryzanol helps increase good cholesterol and reduces bad cholesterol.

You may be interested in How to Grow Hydroponic Cucumber.