Windrow Composting Process

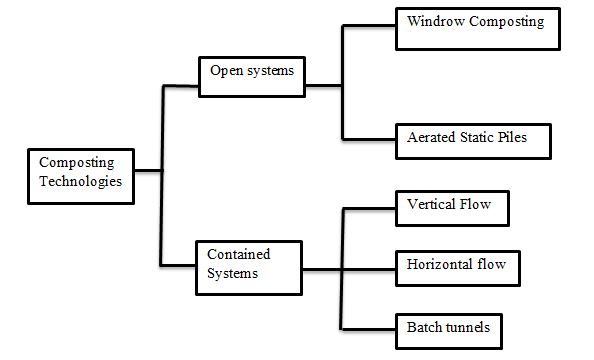

Composting is a successful process because it is a low-cost and low infrastructure set-up and also produces compost, which is a marketable byproduct. Also, to make a positive contribution to agriculture, the sale of organic wastes reduces the amount of waste to be collected and disposed of by municipal authorities. The process of composting is dependent on microorganisms to break down organic matter into compost. Composting process means breaking down organic material. Composting is mainly useful for making inexpensive fertilizer for lawns, gardens, and farms.

Windrow composting is the most common process of composting in India. It mainly involves the stabilization of organic solid waste through aerobic decomposition. Windrow composting process facilities can efficiently handle large quantities of waste in comparison to vermicomposting. It is a process for biodegrading organic material aerobically. The method produces heat that destroys pathogens and also produces a stabilized compost product for use as mulch, soil conditioner, and topsoil additive. Then, the organic material is left to decompose outdoors, aided only by watering and mechanical turning for aeration. This process is simple, non-intensive, has a very low capital cost, and is used by farmers, municipalities, and waste processing corporations. It is the slowest large-scale process used to produce compost. Windrow composting process can be used to process yard waste, food, paper, and sewage sludge.

Windrow composting efficiency and product quality are dependent mainly upon two major factors;

1. The initial compost mix.

2. Management practices.

A Step-by-Step Guide to Windrow Composting Process, Types, Advantages, Disadvantages

What is Windrow Composting?

In agriculture, Windrow composting process is the production of compost by piling organic matter or biodegradable waste like animal manure and crop residues, in long rows (Windrows). Vegetable waste with high moisture content and readily biodegradable nature are causing main environmental problems due to improper waste management practices. Therefore, composting and Vermicomposting can be considered the best alternative for the treatment of these organic fractions.

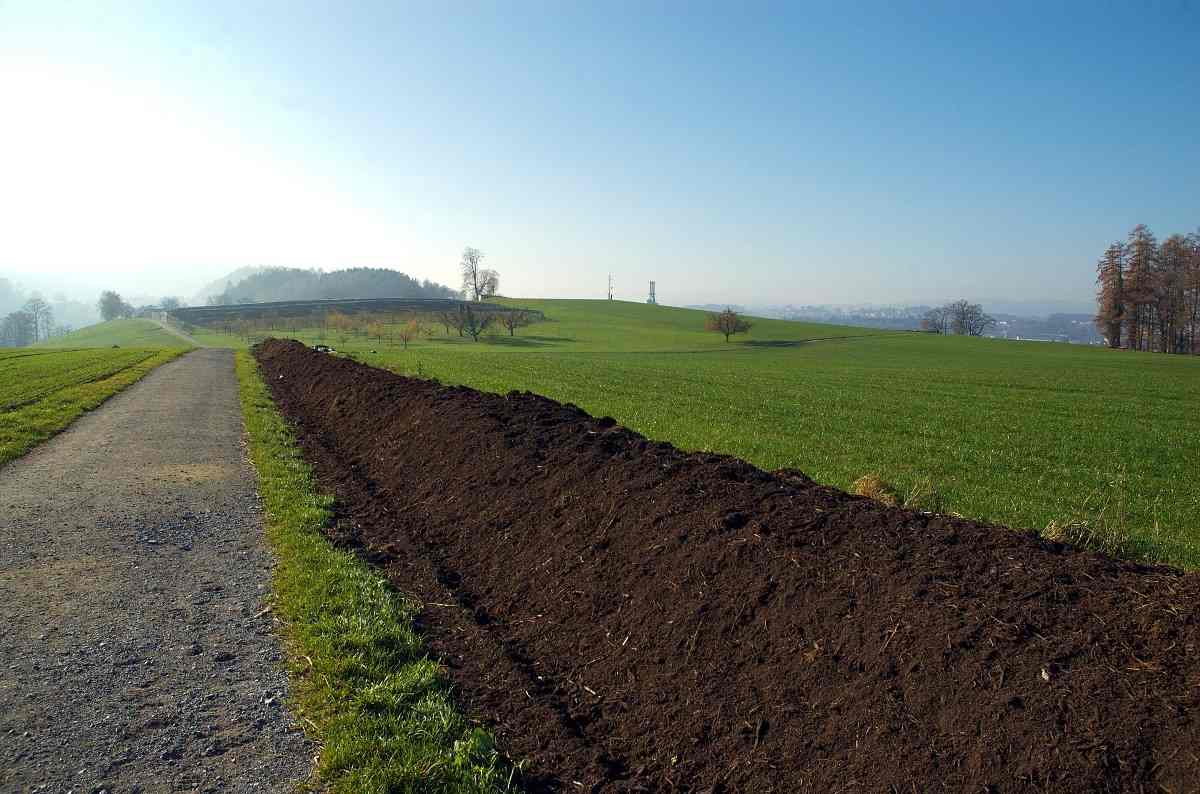

The Windrow composting process is used for processing garden waste, such as grass cuttings, pruning, and leaves in either an open-air environment or within large covered areas where the material can break down in the presence of oxygen. It is conducted by placing raw materials in long narrow piles or Windrows, which are turned regularly. A typical Windrow composting setup must start from 3 feet in height for dense materials like manures and 12 feet high for fluffy materials like leaves. It is costly to support, but it is rapid and retains heat.

Requirements for Windrow Composting Process

Windrow composting requires large tracts of land, sturdy equipment, a continual supply of labor to maintain and operate the facility, and patience to experiment with several materials mixtures and turning frequencies.

How does Windrow Composting Work?

The Windrow composting is an aerobic process wherein the organic material breaks down into CO2 (carbon dioxide), water, minerals and stabilized organic material, while carbon dioxide and water are released into the minerals, atmosphere, and organic matter gets converted into compost. In the Windrow composting method, the organic wastes are piled in elongated rows that are turned regularly. Though, raw materials can be mixed as part of pile formation. Windrow shapes and sizes change depending on climate, equipment and the material used. Usually, Windrows are 2 to 3 m high, 4 to 5 m wide, and up to 30 to 40 m long. Frequent turning of the material (at least once a week) provides aeration, mixes the material, helps to control temperature levels, and redistributes moisture.

Windrows can be left in the open or covered, depending on the climate and the moisture content of the material. Large amounts of heat are lost from small Windrows, especially when they are turned. The turning schedule during composting changes from operation to operation, depending on the pile temperature, season, labor availability, and the desired compost quality. The time required to complete the composting process ranges from 5 to 10 weeks, depending on the type of material being composted and the turning frequency.

Windrow composting process involves aerobic bioconversion of organic matter to stable compost with the release of heat, water vapor, and CO2, in which the pile composting can be used only for small quantities of input materials. In a Windrow composting system, waste is formed into long Windrows that are turned by mobile machines periodically to maintain a stable temperature and decomposition, where water is sprayed to keep appropriate moisture content. These simple Windrow composting where it is turned by machines to aerate can be replaced with a little more sophisticated system, which has a network of pipes that force air into the Windrows are known as “Aerated Windrow systems”. Then, the organic material present in Municipal Waste can be converted into a stable mass by aerobic decomposition. Aerobic microorganisms oxidize organic compounds to CO2 (Carbon dioxide) and oxides of Nitrogen and Carbon from organic compounds are used as a source of energy, while Nitrogen is recycled. Due to exothermic reactions, the temperature of mass rises.

Windrow composting is a used farm-scale composting method. Composting control parameters include the initial ratios of carbon and nitrogen-rich materials, the amount of bulking agent added to assure air porosity, the pile size, moisture content, and turning frequency. This is the commonest form of open composting system where the composting waste is mixed or turned at intervals throughout the composting process. It is used in a large number of centralized composting facilities worldwide and is also the commonest technology used in on-farm composting. Windrow composting takes 12 to 20 weeks depending upon the feedstock used and the expected application of the compost produced. There are several variations of the Windrow process in use.

It involves the arrangement of compost mix in long, narrow piles or Windrows. Turning equipment can range from a front-end loader to an automatic mechanical turner. Generally, Windrows are 4 to 6 feet deep and 6 to 10 feet wide. Windrow composting requires large tracts of land, sturdy equipment, a continual supply of labor to maintain and operate the facility, and patience to experiment with several materials mixtures and turning frequencies.

Climate or Seasonal Considerations for Windrow Composting Process

In warm, arid climate conditions, Windrows are sometimes covered or placed under a shelter to prevent water from evaporating. In rainy seasons, the pile shapes can be adjusted so that water runs off the top of the pile rather than being absorbed into the pile. Also, Windrow composting can work in cold climates. Leachate is liquid released during the composting process. Then, this can contaminate local groundwater and surface-water supplies. It must be collected and treated.

Windrow composting process is a large-scale operation and might be subject to regulatory enforcement, zoning, and siting requirements. Compost must be tested in a laboratory for bacterial and heavy metal content. Also, odors need to be controlled.

Variations of Windrow Composting

There are several possible variations;

Windrows covered with porous sheeting

Some companies offer semi-permeable materials to cover Windrows during the composting process.

Extended Windrow composting

In some facilities very wide Windrows or even a single block of compost many meters square, are used in preference to the narrow Windrows. It is doubtful whether such block achieves adequate aeration.

In-building Windrow composting

In some facilities, Windrows are set up within sealed buildings in an attempt to avoid odour problems. Air can be extracted from the building and processed to remove odours before being released into the atmosphere. Problems can occur with a buildup of bioaerosols and steam within the building under these conditions.

Types of Windrow Composting Process

Passive Windrow Composting

The passive Windrow composting process is the production of compost in piles or Windrows by natural aeration over long periods. Attention to details such as the porosity of the initial mix, uniform product mixing, and particle size greatly improve the speed of the procedure and product quality.

Usually, material to be composted is collected and promptly piled into Windrows, which remain untouched. The materials can be wetted before they are initially formed into Windrows but this is not essential. Though, passive aeration has been successfully used in composting manure from poultry, dairy cattle, and sheep.

Covering the Windrow carefully with a layer of finished compost will help to prevent moisture loss, reduce odour problems, and produce more uniform compost. The center of a Windrow will quickly become anaerobic and by turning can receive a new supply of oxygen. An unpleasant odour will develop in the anaerobic region and begin to emanate from the composting material; hence, a large land area is essential to buffer residents and businesses from the odour. The passive composting process is not very conducive to oxygen presence. Then, rapid composting can take place only in the presence of oxygen; the compost normally will require 3 years to stabilize.

Passive Aerated Windrows

Generally, passively aerated Windrows are Windrows that are not turned. They are used for composting manure with straw or woody shavings and seafood wastes with peat moss. Then, aeration is solely by the passive movement of air through perforated pipes in the pile base.

The Windrows are built on top of a base layer, normally composed of straw, finished compost, or bagasse. This layer should be porous so that air coming through the pile is distributed evenly. Aeration pipes are placed on top of the peat or compost base with their holes oriented downwards to minimize plugging and allow condensate to drain.

A top layer, composed of peat moss and finished compost, is used to cover the Windrow. The main functions of the top layer are to retain odors, moisture, and ammonia and to insulate the pile. Also, it deters flies. As in passive pile composting, it is very important to have a mix with good porosity and structure to allow for adequate aeration. Typically, passively aerated compost systems are 1 to 2 meters high and about 3 meters wide. The bottom and top layers should be about 100 – 150 mm thick. The average composting time is 6 to 10 weeks.

Active Windrow Composting (Turned)

The active Windrow composting process is the production of compost in Windrows using mechanical aeration by a front-end loader or a specially designed Windrow turner. Loaders inexpensive compared to turners, tend to compact the composting material, are comparatively inefficient, and then result in longer composting periods and less consistent quality. Turned Windrow composting process represents a low technology and medium labor approach and produces a uniform product. The most commonly used Windrow turners have a series of heavy tines that are located along with a rotating horizontal drum, which turns, mixes, aerates, and reforms the Windrow as the machine moves forward. These Windrow turners are either self-contained units that straddle the row or are towed by a tractor. The optimum height and width of the Windrows mainly depend on the type of equipment used to turn them.

Compost Windrow Turners

Compost Windrow turners were developed to produce compost on a large scale. They are traditionally a large machine that straddles a Windrow of 4 feet or more high, by as much as 12 feet across. While smaller machines exist for small Windrows, most operations use large machines for volume production. After that, turners drive through the Windrow at a slow rate of forwarding movement. Then, they have a steel drum with paddles that are rapidly turning. The oxygen feeds the aerobic bacteria and thus speeds the composting procedure.

Utilization of Compost Windrow Turner – To accurately use a compost Windrow turner, it is ideal to compost on a hard-surfaced pad. By using 4 wheels drive the Windrow turner is capable of turning compost in Windrows located in remote locations. A self-trailering option allows the turner to convert itself into a trailer to be pulled by a semi-truck tractor. Then, these two options combined allow the compost Windrow turner to be easily hauled anywhere and to work compost Windrows in muddy and wet locations.

The Windrow Composting Site

The Windrow process is best carried out on a concrete base with efficient control over any leachate or liquid runoff produced by the composting. Usually, the concrete is laid so that it slopes slightly in one direction to guide any leachate into an underground sump. The collected leachate can be pumped back onto the compost, or pumped into a tanker and removed from the site. Some systems are set up on soil or hardcore rather than concrete. This approach cannot be recommended for general use because of potential problems with the leachate contaminating groundwater, contamination of the compost with soil or hardcore, and difficulty with vehicle movements during wet conditions.

Most Windrow composting systems are operated in the open air, although there are distinct process benefits in constructing the Windrows under some form of covers such as a Dutch barn or a building. Providing cover in this way will protect the Windrows from becoming too wet from rain and reduce any potential leachate or odour problem. Though there are considerable cost implications in providing cover in this way and many current composting operations would not be able to bear the cost of such an improvement. Also, problems can occur with a Windrow system operated in a building from the steam and bio-aerosols generated, especially during turning. If Windrow composting systems are properly constructed and managed, they can operate effectively without cover.

Windrow Construction

Usually, the size and shape of a Windrow compost pile are based on the equipment used to turn the Windrow effectively. Over-sized compost Windrows will inhibit airflow ensuing in anaerobic conditions and unwanted odours. Compost piles that require less water must be triangular to shed water, whereas compost piles that require additional water must be concave to trap more water. While laying hens can be composted by layering whole carcasses with the carbon-rich and/or bulking material, it is preferable to use the blend and build method of Windrow composting especially when dealing with over 5000 carcasses. Using whole carcasses and building compost piles in layers is very labor-intensive. The tub mixer substantially decreases the labor required to set up the compost pile. Also, it is more difficult to get the compost pile to begin composting when whole carcasses are used because the composting microorganisms do not have the same intimate contact with the carcasses, carbon materials, air, and water as they do when everything is blended. Blending creates a more uniform initial compost mix and then superior conditions for the composting microorganisms. Also, it decreases the volume of the initial mix which will reduce the land area required for the composting site.

In case if you miss this: How To Raise Quails In Backyard.

The Process of Windrow Composting

The process of Windrow composting is simple;

The Windrows are turned regularly to improve oxygen content, distribute heat to regulate temperature levels, and distribute moisture. The Windrows are turned multiple times during the composting process, which takes on average 16 weeks, depending on maturity requirements.

The last part of the procedure involves screening the compost to remove contaminants such as plastics and metals, and to also grade the compost for various end uses. Also, oversized materials are removed and can be put back through the whole process until they have composted down sufficiently. Though, the process of Windrow composting process takes place for 22 weeks in open narrow heaps in which the organic waste is recirculated. Then, the periodically agitated feedstock, food waste, is carried forward to the Windrow and kept in an array of about 1.5 m height and 2 m width. At the time of processing, it is mandatory to expose the compost to favorable conditions like air, light, and temperature through frequent turning so that the compost bacterial population is active throughout the stabilization period. The turning frequency of the compost plays a predominant role in microbial count enhancement and degradation potential, and also it is advisable to turn the compost every week. Generally, composting through the natural aeration mode is observed to be highly successful; meanwhile, the introduction of an air blower in a forced aeration method is observed to be successful in supplying oxygen. Then, this leads to the generation of heat energy with oxidation of carbon to carbon dioxide.

The Benefits of Windrow Composting

Composting is a great recycling procedure in which the resources are conserved in a more available form so that they can be most efficiently used. Unlike chemical and physical disposal processes such as burning and landfill. This biological means of disposing of that is composting can add many benefits to the ecosystem by conserving the plant nutrients. The application of Windrow compost or any other compost can drastically reduce ammonia-type fertilizers usage. In which about 2% of the natural gas consumed use up in the manufacture of these chemical fertilizers.

Some advantages of the Windrow composting method include;

- Rapid drying with elevated temperatures

- Drier product, resulting in easier product handling

- Ability to handle high volumes of material

- Good product stabilization

- Low capital investment

- Easy to implement and operate.

- Handles a large volume of material.

- Low capital costs.

- Less equipment and maintenance needed compared to other composting methods.

- Uses few resources.

This method will yield significant amounts of compost, which might need assistance to market the end-product. Alternatively, local governments can make the compost obtainable to residents for a low or no cost.

Disadvantages of Windrow Composting

- Requires a lot of land for composting.

- Attracts scavengers.

- Often produces odors.

- Requires large buffer zones due to odor and vectors.

- May require a permit depending on size.

- May require the processing of rainwater runoff.

- Compost can become anaerobic in rainy conditions.

- Not space-efficient

- High operational costs

- Piles should be turned to maintain aerobic conditions

- Turning equipment may be required

- Vulnerable to climate changes

- Odors released on turning of compost

- Economical Aquaculture: A Guide to Low-Budget Fish Farming

- 15 Common Planting Errors That Can Doom Your Fruit Trees

- How to Make Houseplants Bushy: Effective Tips and Ideas

- Innovative Strategies for Boosting Coconut Pollination and Yield

- Pollination Strategies for Maximum Pumpkin Yield

- The Complete Guide to Chicken Fattening: Strategies for Maximum Growth

- Natural Solutions for Tulip Problems: 100% Effective Remedies for Leaf and Bulb-Related Issues

- Revolutionizing Citrus Preservation: Towards a Healthier, Greener Future

- Natural Solutions for Peony Leaf and Flower Problems: 100% Effective Remedies

- Maximizing Profits with Avocado Contract Farming in India: A Comprehensive Guide

- Natural Solutions for Hydrangea Problems: 100% Effective Remedies for Leaf and Flowers

- The Ultimate Guide to Choosing the Perfect Foliage Friend: Bringing Life Indoors

- From Sunlight to Sustainability: 15 Ways to Use Solar Technology in Agriculture

- The Ultimate Guide to Dong Tao Chicken: Exploring from History to Raising

- The Eco-Friendly Makeover: How to Convert Your Unused Swimming Pool into a Fish Pond

- Mastering the Art of Delaware Chicken Farming: Essentials for Healthy Backyard Flocks

- 20 Best Homemade Fertilizers for Money Plant: DIY Recipes and Application Methods

- How to Craft a Comprehensive Free-Range Chicken Farming Business Plan