Introduction to Post-Harvest Technology of Cereals, Pulses, and Oilseeds: In today’s world, the importance of pulses, cereals, and oilseeds tremendously increased. If you are a commercial farmer, you must be aware of the post-harvest technology of cereal, pulses, and oilseed crops. Now, let us get into the details of cereals post-harvest technology along with oilseeds and pulses.

The post-harvest technology for cereals

Cereals are seeds or grains of grasses and are cultivated to obtain the largest bounty of their fruit or seed which consists of germ, endosperm, and bran, and is also referred to as the caryopsis. Important cereals in India are wheat, rice, maize, oat, barley, rye, millet, and sorghum. They are an important source of plant food for man and usually provide the bulk of his staple diet. The processing of cereal grains is usually by traditional methods or modern methods. Cereals are the basic ingredients of Indian diets, especially, for people with low-income groups, generally live in rural areas. Each type of cereal crop requires a specific post-harvest treatment; however, certain general principles apply to most of them.

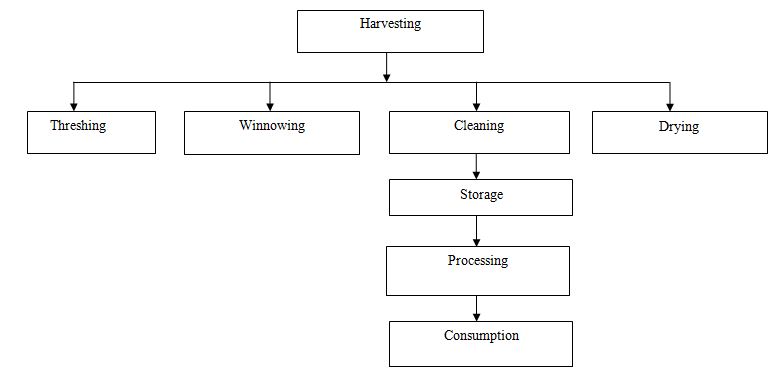

Cereals undergo several processing stages between harvest stage and consumption. This chain of processes is referred to as the total post-harvest system. The post-harvest technology system in Cereals can be split into three distinct areas.

The first is the preparation of harvested Cereal grain for storage. The second is referred to as primary processing, which involves further treatment of the grain to clean it, remove the husk, or reduce the size. Then, the products from primary processing are still not consumable. The third stage (secondary processing) is transforming the grains into edible products.

The primary processing step involves several different processes, designed to clean, sort, and remove the inedible fractions from the grains. Primary processing of cereals includes cleaning, grading, hulling, milling, pounding, grinding, tempering, parboiling, soaking, drying, and sieving.

Secondary processing of cereals (or ‘adding value’ to cereals) is the utilization of the primary products (whole grains, flakes, or flour) to make more interesting products and then add variety to the diet. Secondary processing of cereals includes fermentation, baking, puffing, flaking, frying, and extrusion.

Post-Harvest Technology for Cereals includes the following methods;

Step 1) Harvesting

There is an optimum time for harvesting cereals, mainly depending on the maturity of the crop and the climatic conditions. Then, this has a significant effect on the quality of the grain during storage. Harvesting begins before the grain is ripe and continues until mold and insect damage are prevalent. Grain not fully ripened contains a higher proportion of moisture and will deteriorate quickly than mature grains because the enzyme systems are still active.

Step 2) Milling technology for cereals

Traditional Milling requires the following steps;

- Washing – The grain is washed or rinsed for a short time to soften the outer layers and then hulled at once;

- Pounding – The hulls and bran are detached from the grain by pounding in a wooden mortar for 5 minutes;

- Sun-drying – The pounded grain is exposed in a shallow layer for a short time to facilitate winnowing;

- Winnowing – Most of the hulls and bran (Pigmented layers) are removed;

- Washing – A longer washing to remove remaining hulls by flotation and to increase the moisture content of the grain substantially (from 10 to 12% up to about 25%);

- Resting – A conditioning period in which the grain is exposed to the sun for 1 to 2 hours;

- Pounding – The grain is pounded again for about 5 minutes;

- Sieving – The flour produced in the previous step is hand sieved and collected and the residue returned for further pounding.

If the grain remains in the field after maturing, it can spoil through wetting caused by morning dew and rain showers. There is an increased risk of insect damage. Cereals are traditionally harvested manually and there are three main types of harvesting equipment for the small scale producer. They are manual, animal-powered, and engine-powered. A range of mechanized harvesting equipment appropriate for the small-scale farmer has been developed. Some of it is efficient and cost-effective than others. Harvested crops are left in the field for a few days to dry before further processing.

Step 3) Threshing

The threshing process is the removal of grains from the rest of the plant. It involves three different operations. They are separating the grain from the panicle, sorting the grain from the straw, and winnowing the chaff from the grain.

Separation of the grain from the panicle is the most energy-demanding of the three processes. It is the first procedure to have been mechanized. Sorting the grain from the straw is easy, but is difficult to mechanize. Winnowing is relatively very easy, both by hand and by machine. Manual threshing methods use an implement to separate the grain from the ears and straw. The simplest process is a stick or hinged flail that is used to beat the crop while it is spread on the floor. A range of engine-powered threshers is obtainable.

Step 4) Winnowing

Winnowing process is the separation of the grains from the chaff or straw. It is traditionally carried out by lifting and tossing the threshed material so the lighter chaff and straw get blown to one side while the heavier seeds fall vertically. Hand-held winnowing baskets are mainly used to shake the seeds to separate the dirt and chaff. They are effective but slow. There is a range of winnowing machines that use a fan to create artificial wind and this speeds up the winnowing process. Some of these contain sieves and screens that grade the grains as well.

Step 5) Drying

Before storage or further processing, cereals need to be dried. The cost-effective method is to spread out in the sun to dry. In humid climates, it can be necessary to use an artificial dryer. Simple grain dryers can be made from a large rectangular box or tray with a perforated base. The Cereal grain is spread over the base of the box and hot air is blown up through a lower chamber by a fan. The fan can be powered by diesel or electricity and the heat supplied by kerosene, electricity, and gas or burning biomass. Cereal grains must be dried to 10-15% moisture before storage.

Step 6) Storage

Dried Cereal grains are stored in bulk until required for processing. The grains must be inspected regularly for signs of spoilage and the moisture content tested. If the grain has picked up moisture it must be re-dried. Grains are protected with insecticides and must be stored in rodent-proof containers.

In case if you miss this: Post-harvesting Technology of Fruits.

Post-harvest technology of Cereals flowchart

Hope the above post-harvest technology of cereals will help you to reach your agriculture goals.

The post-harvest management of pulses

Pulses are the dried edible seeds of plants in the legume family and harvested solely for the dry seed. Pulses are nitrogen-fixing crops that develop the environmental sustainability of annual cropping systems. Pulses come in a variety of shapes, different sizes, and colors and can be consumed in many forms including whole or split, ground into flours, or separated into fractions such as protein, fiber, and starch.

Post Harvest Management of Pulses is;

Step 1) Harvesting

Harvesting of pulse crops is normally done by hand with simple farming implements like a sickle or by machines when the pods are ripe but not yet open. To harvest the pulse crops by hand, the plants are pulled up and allowed to pre-dry in the sun. This operation must be done early in the morning, while the dampness of the night minimizes the risk of shattering losses. In some places, before the harvest, the plants are treated with chemical defoliants. This treatment is intended to hasten the drying of the plants and then reduce the quantity of plant matter to prevent it is slowing up threshing operations. On average, it takes about 80 to 100 man-hours per hectare to cut the plants by sickle.

Pulses constitute essential components of a vegetarian diet and pulses are a major source of protein in the Indian vegetarian diet. Then, these are the main source of protein providing most of the essential amino acids to a certain degree. Economically, pulses are the cheapest source of protein. Major Pulses in India are Bengal gram, pigeon pea, black gram, green gram, and lentil, etc. Pulse crops are consumed in the form of dehusked split pulses, as these are rich in proteins.

Step 2) Pre-drying

Pre-drying is the stage of the post-harvest system during which the harvested product is dried to undergo the next operation of threshing, under the best possible conditions.

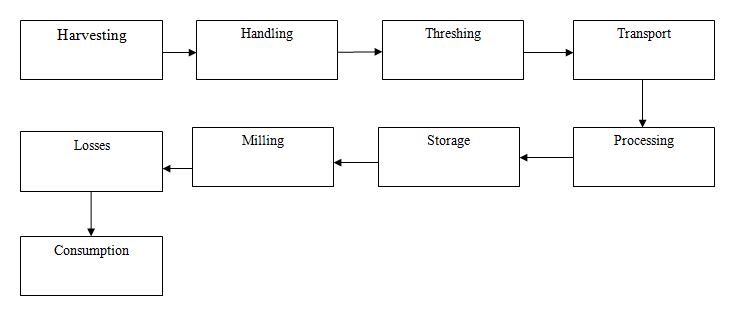

Step 3) Threshing

The threshing process is the operation of separating the grains from the plants. These operations can be carried out in the field or on the threshing floor, by hand or with the help of animals or machines. Whatever the system used, it is important that threshing is done with care. Otherwise, these operations can cause breakage of the grains or husks, thus reducing the quality of the product and subsequent losses from the action of insects and molds. Care should be taken while transporting the harvested crops from the field to the threshing floor to avoid any loss.

Step 4) Drying

After threshing, the moisture content of grains remains higher than the desired for safe storage of grains (13-14%). The drying process is the phase of the post-harvest system during which the product is rapidly dried until it reaches the “safe-moisture” level. Drying aims to lower the moisture content of the grain for safe storage and processing. For drying grain, essentially two methods. They are natural drying and artificial drying is used.

The natural drying consists essentially of exposing the threshed products to the air (in sun or shade). To get the desired moisture content, the grain is spread in thin layers on a drying-floor, where it is exposed to the air. The duration may vary depending upon the moisture content necessary for safe storage. In the artificial drying process, heated air (dryers) or unheated air (dehumidifiers) is blown through a grain mass.

This is the widest spread practice in semi-humid conditions and humid conditions where natural drying cannot be used. Artificially heated air is forced to flow through a mass of grain in bulk or bags to absorb released moisture from grain mass.

Step 5) Storage

The storage process means keeping the products in a manner that guarantees food. Pulses can remain in edible condition for several years if correctly stored. Though, pulses are more difficult to store than cereals and suffer much greater damage from insects and microorganisms. This not only results in quantitative losses but also in qualitative reduction of the nutritive value. The milling losses in insect-damaged grains are even higher as breakage and powdering occur with such grains. Pulses are susceptible to infestation, both in the field and during storage, by weevils, which are prolific, breed rapidly, and then cause serious deterioration in the nutritive value of the grain. Damage ranging from 30 to 70% of the grain has been reported in various publications. At 30°C and 70% relative humidity (RH), some species of bruchids take only a few weeks to develop from egg to pupa. Higher humidity is conducive to the more rapid proliferation of all species.

Post-harvesting technology of Pulses flowchart

Post-harvest technology of agriculture oilseeds

You may also like this: Cold Storage Subsidy, Loan, and Business Plan.

Oilseeds are seeds grown mainly for the production of edible oils. Oilseeds are a high-value agricultural commodity for use in refined edible oil products. As the world population increases, demand for high-quality seed oils continues to grow and the presence of polyunsaturated fatty acids in sesame oil makes sesame an important oilseed crop due to its excellent health effects. Oilseeds add important nutritional value to the diet by high-quality protein and vegetable oil, together with oil-soluble vitamins like vitamin A. The major oilseeds of India are groundnut, soybean, rapeseed mustard, linseed, sesamum, and castor. Groundnut and rapeseed mustard account for 85 percent of the total production of oilseeds in the country.

Measures to improve oilseed production

Key measures to improve oilseeds production contain;

- Bringing additional oilseed areas under irrigation

- Promotion of modern crop technology

- Promoting oil palm cultivation

- Further, there is a need to enlarge the scope of research, technology diffusion, and institutional intervention to re-energize the oil sector. This includes increasing public research spending in oilseed crops for the development of biotic and abiotic stress-tolerant varieties.

- Strengthen the oilseed crop seed chain, mainly in groundnut to match the variety of specific demand for higher yield.

- Provide incentives to private sector participation in processing and value addition in oilseeds. Also, constraints for low capacity utilization must be addressed.

Apart from this, other measures include market reforms and policies, such as contract farming and public-private partnership in production and processing, to ensure a competitive market for oilseeds and edible oil along with adequate protective procedures to avoid unfair competition from the international markets.

Post-harvest technology of oilseeds is;

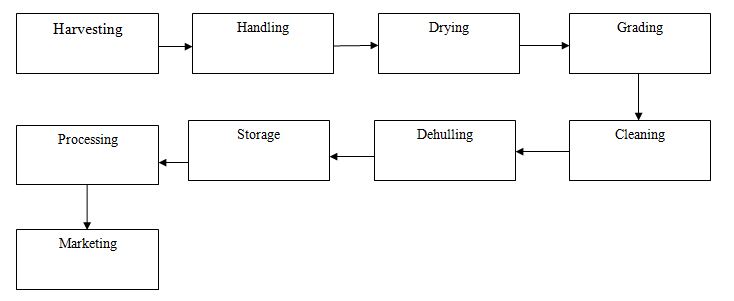

Post-harvest technology plays a key role in minimizing losses during handling, processing, and preservation of oilseed crops and their products. By adopting proper post-harvest technology, the input cost in the processing of oilseeds is reduced and the oil yield is increased. Besides, several values added products can be produced even at a rural level by the introduction of appropriate post-harvest technology and the farmers can be motivated to grow more oilseeds.

Handling, drying, and storage

Proper handling and storage of oilseeds are very important for their processing into quality products since oilseeds are prone to autocatalytic deteriorative processes, enzyme action, and microbial spoilage, etc. Immature seeds, harvested before their enzymes have become dormant, deteriorate rapidly than normal seeds during storage.

Grading

Grading of oilseeds is required to establish their general quality based on soundness, moisture content, and freedom from impurities and to evaluate their oil milling quality based on yield and quality of the oil. The grade specifications of different oilseeds are based on (i) quantity of non-prime seeds including damaged, insect-infested seeds, slightly damaged seeds, shriveled and immature seeds, (ii) type and quantity of impurities or foreign matter, (iii) moisture content of seeds, (iv) oil content, and (v) color, acid value, iodine value and other indices of quality of extracted oil.

Cleaning

Normally, the oilseeds are mixed with a variety of foreign materials such as sand, stones, stalks, weed seeds, and foliage, etc., during harvesting, handling, and transportation. It is ideal to clean seed before putting it into the store.

Post-harvesting technology of Oilseeds flowchart

In case if you are interested in this: Sunflower Oil Production Business.