Biofloc Technology (BFT) is seen as a new “blue revolution” since nutrients can be regularly recycled and reused in the growth medium while minimizing or eliminating the need for water exchange. BFT is an aquaculture technology based on in-situ microbe generation that is environmentally favorable. Biofloc is the aggregation of live and dead particle organic matter, phytoplankton, bacteria, and bacteria grazers that form suspended growth in ponds/tanks.

It’s the use of microbial activities within the pond/tank to supply food resources for cultured organisms while also acting as a water treatment solution. As a result, active suspension ponds, heterotrophic ponds, and even green soup ponds are all terms used to describe this system. Let’s check out a way of earning 10 lakh per year from Biofloc fish farming.

How does BFT work?

The Biofloc system is a wastewater treatment system that has become more important in aquaculture. The technique’s concept is to maintain a greater C-N ratio by adding a carbohydrate supply and to enhance water quality by producing high-quality single-cell microbial protein.

Heterotrophic microbial growth occurs in this situation, which assimilates nitrogenous waste that may be used as a feed by the cultured species and serves as a bioreactor for water quality management. Because heterotrophs’ growth rate and microbial output per unit substrate are 10 times larger than autotrophic nitrifying bacteria, hazardous nitrogen species are immobilized more quickly in biofloc.

Composition and nutritional value of biofloc

Biofloc is an extracellular polymeric material containing a heterogeneous aggregation of suspended particles and a diversity of microorganisms. It is made up of bacteria, algae, fungus, invertebrates, and detritus, among other microorganisms. It’s a protein-rich live feed created when wasted feed and excreta are converted into natural food in a culture system after being exposed to sunshine and intense aeration. Each floc is kept together by a loose mucus matrix produced by bacteria and held together by the spread of germs or electrostatic attraction.

In case you miss this: Biofloc Fish Feeding Chart – Per Body Weight

The majority of the flocs are tiny and range from 50 to 200 microns. Biofloc contains a high nutritional value. Protein content varies between 25 and 50 percent by dry weight, whereas fat content varies between 0.5 and 15%. It contains a lot of vitamins and minerals, especially phosphorous. It has a similar effect as probiotics. Dried biofloc is being recommended as a feed additive to replace fishmeal or soybean.

Advantages of using BFT system

- Culture system that is environmentally beneficial.

- It has a lower environmental effect.

- Using land and water in a useful manner.

- Water exchange system with limited or no water exchange.

- Higher productivity (in fish culture systems, it improves survival rate, growth performance, and feed conversion).

- Biosecurity is ensured.

- Reduces water contamination and reduces the possibility of disease introduction and dissemination.

- It lowers the expense of conventional feed while increasing the consumption of a protein-rich diet.

- It relieves strain on capture fisheries by allowing for the use of less expensive food fish and garbage fish in the composition of fish feed.

Disadvantages of using BTF system

- An increase in the amount of energy required for mixing and aeration.

- Reduced response time due to increased water respiration rates

- A start-up stage is necessary.

- Supplementing with alkalinity is necessary.

- Accumulation of nitrates has the potential to pollute the environment.

- Sunlight-exposed systems have inconsistent and seasonal performance.

In case you miss this: Biofloc Shrimp Farming (Prawn) – a Full Guide

Fish species that can be cultivated using the BFT method

The type of species to be cultivated is an important consideration when developing a biofloc system. The Biofloc technology usually works with species that can gain nutritional advantages from direct floc ingestion. The Biofloc system is best for species that can withstand high solids concentrations in water and are resistant to poor water quality generally. The following species are suited for BFT:

- Magur, Pabda, Singhi, Anabas/Koi, and Pangasius are all air-breathing fish.

- Fish that do not breathe air, such as common carp, tilapia, rohu and milkfish.

- Vannamei and Tiger Prawn are examples of shellfish.

Earning 10 lakh per year from Biofloc fish farming

The success story of Mr. Shravan Kumar

Mr. Sravan of Guntur district, Telangana studied M.Sc. in organic chemistry in a popular government college and worked as a chemical engineer in a private company. As he lacked satisfaction and interest in the job he was doing, he wanted to start something on his own, which lead to the starting of his biofloc fishery farm. He analyzed the major cattle and fishery ventures from which he can obtain high profits.

In case you miss this: Questions about Biofloc Fish Farming with Answers

As he is an educated individual with high knowledge in science, he wanted to use new end technology in whatever he choose to do. When he decided to start fish farming, unlike others who rears fish in ponds, he wanted to use biofloc technology. He learned this technique from a university professor and also joined as a trainee under him for two months. After completely gaining knowledge on how to rear fish using biofloc technology he immediately started investing in his farm.

Mr. Sravan said he really liked the BFT technique and wanted to experiment with the fish culture by using this technology. He strongly believes that this technique is the answer for the growing population since it has the potential to fulfill the need of growing demand.

If we want to cultivate the fish by ponds or other methods, it takes a high investment, and the yield is low when compared to the fish yield produced by this method. BFT method also takes low investment but should be done carefully by undertaking proper management. The fish that are produced by a 1-acre pond can be produced by only 10 cents (0.1 acres) of land by the BFT method, says Mr. Sravan.

Construction of tanks according to Mr. Sravan

It took 5 months for the whole construction and land preparation purposes for Mr. Sravan. He constructed two poly sheds with a length of 100 feet and a width of 30 feet and built 8 tanks in them for rearing fish in them. The diameter of each tank is 8 meters, and each tank has a capacity of nearly 50,000 litres. The sheds should be mandatory for fish since it protects them from the sun and other harsh environments.

Before constructing the tanks, you must prepare a basement with the same diameter by which you will build the tanks. For building the tank don’t use cement since it is costly. You can use a mesh ring of the same diameter to put on the basement, and you can cover it with a protective sheet. After this spread a tarpaulin sheet and stuff it inside till it reaches the basement. Once done the tank should be able to hold water, if not you probably did a mistake while constructing the tank.

Each tank should be constructed perfectly and shouldn’t have any leaks. Mr. Sravan suggests that farmers use quality cement or quality framework and material while constructing the tanks, depending on the type of tank they want to construct. It cost him nearly 10 lakhs for constructing the sheds and tanks, which is a bit high investment but can be erased soon as it is a one-time investment cost.

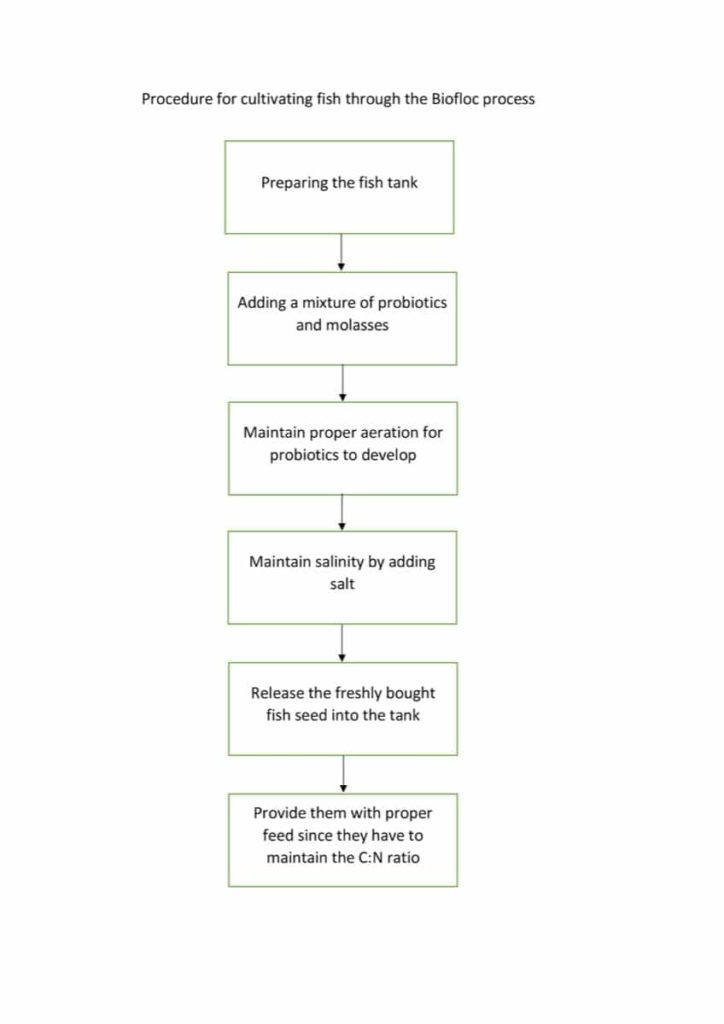

Cultivating fish using bioflock system according to Mr. Sravan

He chose pangasius fish to cultivate in his tanks. When asked about it, he said that it is very important while choosing the species of the fish. Most fishes can be cultivated by biofloc system but not all. He initially thought of cultivating Catla or Rohu, but they are available everywhere, so instead of that, he chose to cultivate pangasius species as this species is also suitable to be cultivated by biofloc system.

In each tank, he stocked nearly 2500 fish for cultivating. It cost him nearly 7 rupees per 7-inch pangasius fish, including transportation. As he is new to this culture his farm is experiencing a 20 % death rate in fish. He expressed that since it is starting, he is learning to gain knowledge from the mistakes he did while cultivating using this technology.

For cultivating purposes there is pipe used in the middle of each tank placed at the bottom for drainage of fish waste when allowed. You can control this pipe with a tap separately for each tank. Once the tap is on, the waste that is stored at the bottom is immediately flushed out. You can reuse this wastewater to feed the fish again in the biofloc system.

Keep in mind that you are not feeding the fish directly, you are just aiding the growth of microbes, which can also be called probiotics. These probiotics when grown in our tanks, ensure the water quality and get eaten by fishes as feed. These probiotics are rich in protein as they are developed by the fish excreta which is produced from high protein feed given to fish from us. As a result, the probiotics become a rich source of protein for the fish when consumed and provide a good yield, resulting in higher profits.

In case you miss this: Cost of Biofloc Farming, Biofloc Setup Cost, Disadvantages

You can help microbes to grow with aeration by using blowers. These blowers are connected through various pipes and released into the tanks for aeration purposes. These pipes are again connected to AirOxy tubes, which are circular and contain nozzles. When the air is flown into these tubes you can observe the bubbles coming out from inside of the tank. 10 AirOxy tubes are provided for each tank.

You can control and monitor aeration for each tank separately by using switches. He set his aeration scale on point 10 for providing adequate aeration for the microbes to grow adequately which can be consumed by fish. These aerators should run 24 hours non-stop and in case something happens, and aeration stops you will have a maximum of two hours to fix the issue and start aerators again before it affects the fish.

Mr. Sravan used two blowers on his farm each one cost him nearly 70,000 rupees. These blowers are connected to a generator with the help of which these machines run. It also shows the pressure at which it blows the air into the tanks, and you should set this pressure accordingly. Huge pressure can result in the death of seed and low pressure cannot help them grow quickly.

While researching about the type of fish you want to cultivate, you should also gather information about the aeration required for the fish in the tanks. These machines are like the heart of the biofloc system. You cannot cultivate fish by the BTF method without using these blowers. He uses a 10 kV generator for the blowers to run in case the power gets cut. This generator cost him nearly 3 lakh rupees.

He uses a high protein feed to provide for the fish. It cost him nearly 35,000 rupees per ton for buying this 24% protein feed. This feed can make microbial organisms grow in the tanks providing for the water quality and at the same time serving as food to the fish. These microbes are rich in protein and when fish consumes this it can aid in the quick and quality growth of the fish.

Even for the diseases, only organic medicine is used such as turmeric, bitter gourd, garlic etc. Using medicine that involves chemicals can be unhealthy for fish and can affect your yield. Pangasius fish when cultivated by this system can grow up to 800 grams to 1 kg of fish. For a fish to reach this stage it feeds on nearly 1.3 kgs of feed till the time of harvesting. Mr. Sravan spent nearly 5 lakhs on feed costs for his farm and now he is expecting a minimum of12 tons of yield from his farm.

In case you miss this: Biofloc Technology (BFT) In Aquaculture, India – A Full Guide

Marketing and profit analysis of Mr. Sravan’s farm

The running cost of Mr. Sravan’s farm is nearly 8 lakh rupees. And he says he is expecting at least 12 tons of yield from his farm. And he sells his fish at nearly 150 to 190 rupees per kg at the wholesale. Assuming 150 rupees as the least pricing conditions at which Mr. Sravan sells his fish, means he will be earning an income of rupees 18 lakh per batch. Erasing the investment cost from this, the total profit he obtained is nearly 10 lakhs for a batch.

As each batch lasts a year, Mr. Sravan is earning rupees 10 lakhs as a profit per year from pangasius fish culture using the biofloc system. He suggests young farmers enter this type of venture which uses advanced ideas and also wants them to spread proper awareness among people about the biofloc system. Before entering this business, he wants the farmers to gain proper knowledge about the type of fish they want to cultivate and learn about the care and management needed for cultivating fish in the biofloc system.

Mr. Sravan is now a proud owner of his biofloc fish farm earning high profits by cultivating pangasius using the BTF technique. He expresses that he is happy and satisfied by the work he is doing now, unlike when he was working for a private company as a chemical engineer.

- Types of Pesticides Used in Agriculture: A Beginner’s Guide

- Economical Aquaculture: A Guide to Low-Budget Fish Farming

- 15 Common Planting Errors That Can Doom Your Fruit Trees

- How to Make Houseplants Bushy: Effective Tips and Ideas

- Innovative Strategies for Boosting Coconut Pollination and Yield

- Pollination Strategies for Maximum Pumpkin Yield

- The Complete Guide to Chicken Fattening: Strategies for Maximum Growth

- Natural Solutions for Tulip Problems: 100% Effective Remedies for Leaf and Bulb-Related Issues

- Revolutionizing Citrus Preservation: Towards a Healthier, Greener Future

- Natural Solutions for Peony Leaf and Flower Problems: 100% Effective Remedies

- Maximizing Profits with Avocado Contract Farming in India: A Comprehensive Guide

- Natural Solutions for Hydrangea Problems: 100% Effective Remedies for Leaf and Flowers

- The Ultimate Guide to Choosing the Perfect Foliage Friend: Bringing Life Indoors

- From Sunlight to Sustainability: 15 Ways to Use Solar Technology in Agriculture

- The Ultimate Guide to Dong Tao Chicken: Exploring from History to Raising

- The Eco-Friendly Makeover: How to Convert Your Unused Swimming Pool into a Fish Pond

- Mastering the Art of Delaware Chicken Farming: Essentials for Healthy Backyard Flocks

- 20 Best Homemade Fertilizers for Money Plant: DIY Recipes and Application Methods

- How to Craft a Comprehensive Free-Range Chicken Farming Business Plan

- Brighten Your Flock: Raising Easter Egger Chickens for Beauty and Bounty

- How to Optimize Your Poultry Egg Farm Business Plan with These Strategies

- Subsidy for Spirulina Cultivation: How Indian Government Schemes Encouraging Spirulina Farmers

- Ultimate Guide to Raising Dominique Chickens: Breeding, Feeding, Egg-Production, and Care

- Mastering the Art of Raising Jersey Giant Chickens: Care, Feeding, and More

- Ultimate Guide to Raising Legbar Chickens: Breeding, Farming Practices, Diet, Egg-Production

- How to Raise Welsummer Chickens: A Comprehensive Guide for Beginners

- How to Protect Indoor Plants in Winter: A Comprehensive Guide

- Ultimate Guide to Grow Bag Gardening: Tips, Tricks, and Planting Ideas for Urban Gardeners

- Guide to Lotus Cultivation: How to Propagate, Plant, Grow, Care, Cost, and Profit

- Agriculture Drone Subsidy Scheme: Government Kisan Subsidy, License, and How to Apply Online

- Ultimate Guide to Raising Araucana Chickens: Breed Profile, Farming Economics, Diet, and Care

- Bringing Hydroponics to Classroom: Importance, Benefits of Learning for School Students

- Ultimate Guide to Raising Polish Chickens: Breed Profile, Farming Economics, Diet, and Care

- Ultimate Guide to Raising Australorp Chickens: Profile, Farming Economics, Egg Production, Diet, and Care

- Silkie Chicken Farming: Raising Practices, Varieties, Egg Production, Diet, and Care

- Sussex Chicken Farming: Raising Practices, Varieties, Egg Production, Diet and Care

I am interested in training in Biofloc fish farming, can you possibly link me up with Mr Sharvan Kumar to train with him, (on the job training) for 8 weeks. I will really appreciate your assistance it’s very important to me please.

I want to set up this farm… Having land 500 /sq meters.. Plz guide us…